views

The process of producing cement involves three main steps - preparing the raw materials, clinker calcination and grinding the cement. Clinker refers to the material that is produced in the second stage and it is quite often used as the binder in several cement products. Thus, it is essentially a semi-finished product made up of clay, limestone, iron raw materials, etc mixed in the right proportions. This mixture is then partially or completely melted and it finally cools to a normal temperature to form clinker. This process involves the use of a number of machines that can be procured from cement plant machinery manufacturers.

Three Clinker Production Machines You should know about

One of the most commonly used materials in the construction industry is the Portland cement clinker. It consists of silica, calcium oxide, and trace amounts of iron oxide and alumina. Its particles are dark gray in color and usually, they are of the size of 3 to 25 mm. It can easily be stored for months together without any degradation in its quality. Needless to say, it is traded even across borders especially if raw materials are scarce. Just like you’d approach Flux Cored Wire Suppliers in India for flux wires, you can also approach cement manufacturers for the right cement.

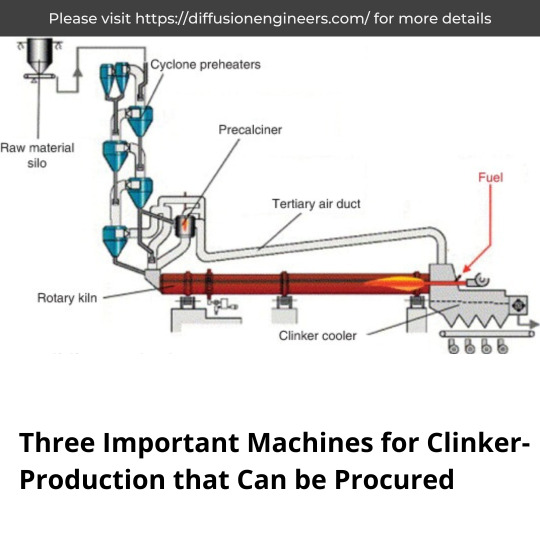

Cement production can also be categorized into two processes - dry and wet. Dry process is used most commonly because it offers high output with low consumption of heat as well as runs steadily. The dry process includes three main models. Among these models also, the calcination of clinker can be divided into preheating and clinker cooling. Given that some parts of the plant have to bear heavy temperatures, it is important to look after them. Make sure to procure some thermal spray powder from thermal spray powder suppliers for the upkeep of your machines. The three main clinker production machines are as follows:

Cyclone Preheater

This one is also known as the suspension preheater and it is one of the most crucial pieces of equipment in the process of pre-heating and pre-calcining. It is much different from the stack heat-transferring mode that takes place in the rotary kiln. The material that is inside the preheater comes completely in contact with the hot air. Given the large area of contact, the speed of the heat transfer is quite quick and exchange takes place efficiently.

Cement Kiln

Sintering of the clinker is an important step of calcination of clinker and this takes place in the cement kiln. Within the kiln, the raw materials are first heated by increasing the temperature and this helps in creating a series of chemical and physical reactions. Once the temperature reaches the highest point, the clinker is produced rapidly by cooling.

Clinker Cooler

Also called the cement cooler, this part is situated right after the cement kiln for cooling the clinker. Within the cement plant, rotary cooler and grate cooler are usually used for daily production. Inside the cooler, the hot clinker directly comes into contact with cooled air which helps in quick cooling.

Conclusion

All of the aforementioned machines can be availed easily from Cement plant equipment suppliers. However, make sure that you are aware of the parts that you need and select high machines that can last you for a long time.