views

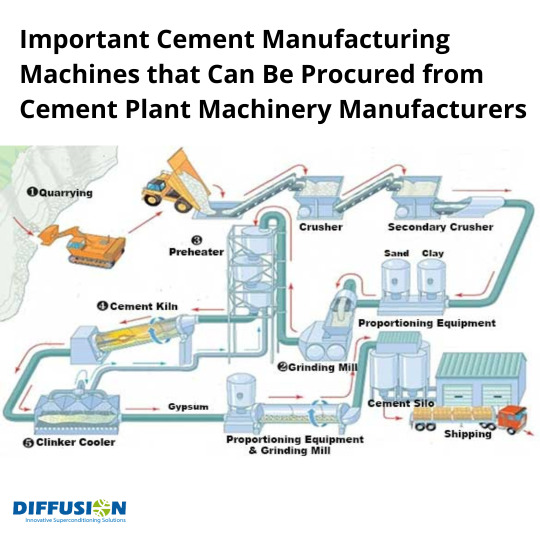

The construction industry is what keeps nations across the world going - from roads to buildings, from offices to houses, without the construction industry, the world would come to a standstill. And one of the most crucial parts of this industry is cement. Irrespective of the construction taking place, cement has to be used. Hence, it is also often called ‘food for the construction industry.’ And as the development across the world skyrockets, so does the demand for cement. Cement can be produced with the help of machines procured from Cement plant machinery manufacturers.

Crucial Cement Manufacturing Machines You must know about

With the continuous transformation of the cement industry, several efficient, environmentally friendly, and energy-saving machines are being developed every single year. Thus, if you want to work in the construction industry, there are some crucial construction machines that you must know about. These machines will also need timely maintenance to ensure their durability. Producing thermal spray powder from Thermal spray powder suppliers can be immensely helpful. The following are some important machines that you must procure if you plan to produce cement:

Rotary Kiln

This is the core equipment of cement plants and it is responsible for the calcination of clinker. This is used both for the dry as well as the wet production process. It is kept horizontally with an angle to the ground. This forms a state of a high and a low end. The body of the kiln rotates slowly driven by the engine. The fuel is injected through the kiln head and it is burned in the kiln to produce heat. Raw materials enter through the high end and they proceed towards the low end in a slowly rotating manner.

Shaft Kiln

Also known as a vertical kiln, this one is a standing and non-rotating cement kiln. This machine is also used for wet and dry cement production lines. The inside of the shaft kiln is divided into different zones - preheating, calcination and cooling. These zones occur in a vertical manner from the top to the bottom. Raw materials enter from the top feeding port and move down towards their own weight. During this process, heat is exchanged through the hot gas and this produces physical and chemical changes.

Cement Mill

A grinding mill for clinker is also known as a cement mill. It is an equipment that is used for grinding calcined clinkers. It essentially helps the particles reach the fineness that is required for the job. It is one of the core pieces of machinery in the last step of the process of producing cement. There are three types of cement mills - vertical mill, ball mill, and roller press. A cement vertical mill merges all the steps of cement production into one. The cement ball mill uses continuous rotation for reducing the size of the clinker. The roller press is a relatively new form of machine that is used as a pre-grinding system. All of these different types of cement mills can be purchased from Cement plant equipment suppliers.

Conclusion

Apart from the aforementioned crucial machines, there are other machines that are used for cement production as well. Just like how you can procure fluxed cored wires from Flux Cored Wire Suppliers in India you can procure cement-producing machines from leading suppliers as well.