views

1. Boosts Productivity.

The use of HMIs in the worksite will certainly increase productivity. An HMI can be used to automate original manual tasks. The use of HMI systems can eliminate the need for employees to perform manual tasks such as lifting or manipulating objects. As a result, workers can devote their time and effort to other tasks due to this. An extensive range of devices and machines can be linked together using Human Machine Interfaces, which improves their ability to communicate while also providing new functionality.

2. Reduces Hardware Cost

This alone should be sufficient justification for businesses to invest in HMI solutions. It is possible to significantly reduce the total cost of hardware by utilizing Human Machine Interfaces. A single Human Machine Interface can maybe end up replacing dozens or even hundreds of individual "indicator" lights, lowering the cost of unnecessary hardware and attempting to make efficient use of the available room.

3. Prevents Work Injuries

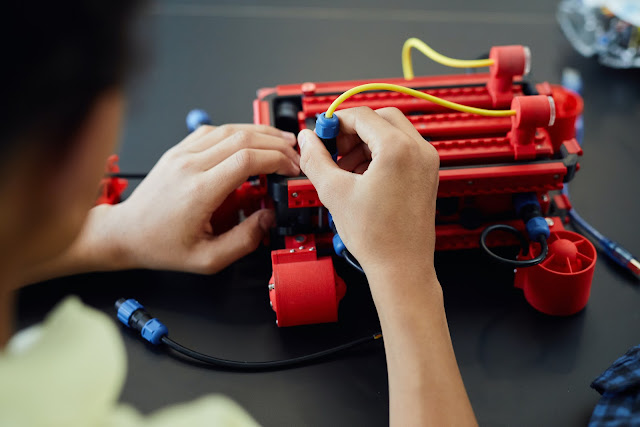

Every year, around 4,000 - 10,000 workers are killed or seriously injured, with thousands of them suffering serious injuries. The use of Human Machine Interfaces, on the other hand, can help to reduce such figures by protecting workers from frequent types of accidents and illnesses. A human-machine interface (HMI) solution can free workers from the burden of manually operating a machine by automating the process.