views

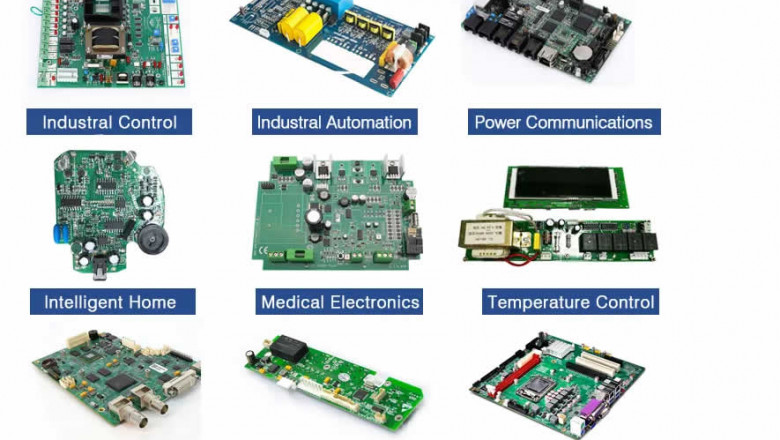

Autodesk Eagle is a very handy tool for PCB design and layout. It has scripting features that allow us to automate the electronic design process. Once you complete the design of your PCB board in Autodesk Eagle, the next step is to generate a Gerber file. This is because you will have to send this Gerber file example along with your other design files to your PCB manufacturer. One of the best things about Autodesk Eagle is that it includes a very intuitive CAM processor. This module allows us to import any CAM file and then immediately generate any kind of file that you may need for your PCB board. So, you can use this functionality to generate the required Gerber file.

1) Open the CAM processor

Open the CAM processor

You will first have to import and open the PCB layout file in Autodesk Eagle. The PCB layout file has a (.brd) extension. So, for opening it you can click the CAM button. Alternatively, you can do this by first clicking on File and then navigating to the CAM processor. Doing this will immediately open the CAM processor that we are going to use for generating the Gerber files. weight less

2) Navigate to Job

Navigate to Job

The next step is navigating to the job. You can do this by clicking on File and then clicking on open. Then toggle the job button.

2) Open the gerb274x.cam file

You will have to first navigate to the default CAM folder of your Autodesk Eagle. So, from there you can choose the gerb274x.cam file. Once you have done that, you can select open.

3) Add a second silkscreen

If you browse through the tabs in Autodesk Eagle then you will observe that we do not have any file for the bottom silkscreen layer. This is because, in the case of simple hobbystar PCB boards, we usually place the silkscreen only on the top layer. However, if you have a complex PCB and you want to add an additional silkscreen on the bottom layer, then you can do that as well.

First of all, you will have to click security camera on Add.

Then you will have to change the section. You can use any relevant term such as “Silk Screen Bottom”

After that, you will have to change the fie to “%N.pls”

Then you will have to deselect all the layers

Then select these layers: 26 “bNames, 20 “Dimension, and 22 “bPlace”

4) Create a Gerber File

Create a Gerber File

You can now finally create your required Gerber file. For this purpose, you will have to click the Process Job button. Then you will see that your required Gerber file is generated in the project folder of your Eagle control panel.

5) Sending the Gerber File to kingfordpcb Technology

Once you have generated the Gerber files, you will have to send them to kingfordpcb Technology so that we can start processing your order. For this purpose, you will have to put together all of your Gerber files and zip them in a single folder. Then you can upload this zip file to the order page of kingfordpcb Technology. This will allow us to receive the Gerber files along with your order specifications. Hence, we will start working on it right away.

Common mistakes of Gerber file from eagle and how to solve it

1) Missing drill files

We need these files for determining the location and size of the holes that we are about to drill in a PCB board. If you forget to include these files then your PCB manufacturer can face a significant amount of difficulty.

2) Missing solder mask layers

If your PCB board has two or more layers then the files must have two solder mask layers. One is for the top layer and the other is for the bottom layer.

3) Missing or double outlines

One of the most common mistakes is that people often generate files that lack outlines. These outlines are important for identifying where to cut the PCB boards. Sometimes people mistakenly generate files where they include two or more boxes around the PCB board. In both of these scenarios, the PCB manufacturer can face severe problems.

4) PCB size mismatch

Often the dimensions of the PCB board entered in the order do not complement the dimensions entered in the Gerber file. You should avoid so that we can prevent any significant delays in PCB manufacturing.

5) Placement of Drill holes cut into the tracing

Sometimes people mistakenly place the drill holes in such a way that they interfere with the circuit tracing. On top of that, they forget to reroute the tracing around the hole. You should avoid this so that the functionality of the PCB board is not damaged.

6) Plated and non-plated holes are not clearly defined in Gerber File

Sometimes people lack a fundamental understanding of how the Gerber PCB software differentiates the NPTH from the PTH. In Autodesk Eagle, you can make the NPTH by using the hole tool. On the other hand, you have to use the Via tool for making the PTH.