views

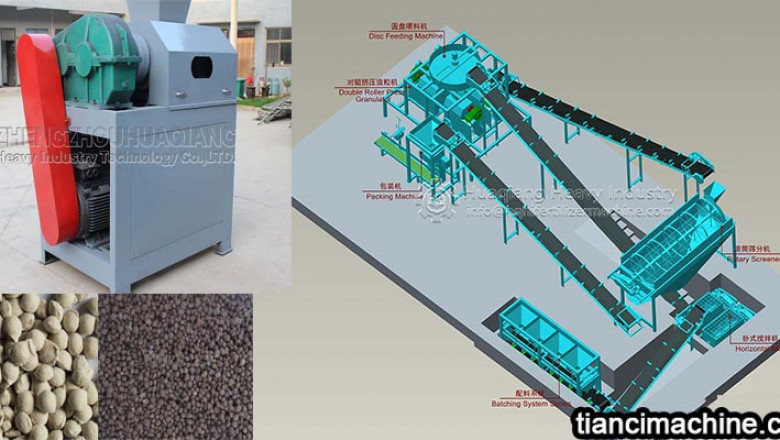

Extrusion granulator can produce organic fertilizer, compound fertilizer, compound fertilizer and other fertilizer products. It has a wide range of applicability, which can be used as organic fertilizer granulator machine or NPK fertilizer granulator. The following is to share with you the process of extrusion granulator in processing. The production of compound fertilizer by extrusion granulator can be divided into four main processes as follows:

1. Urea, ammonium phosphate, potassium chloride and other raw materials are transported to the silo for storage, metering and mixed fertilizer by bucket conveyor and belt. The number of silos, the complexity of metering and mixing skills are related to the number of components in the product formulation.

In the production of compound fertilizer, batch mixing operation is generally used. The ingredients in the formula are weighed in a weighing box. After meeting the formula requirements, all ingredients are mixed in a batch mixer. The balance bin is installed in the system and connected with other equipment after operation. drum granulator

Trace elements can also be added to the blender. In order to ensure the uniform distribution of trace elements, a high-strength agitator was selected.

After the progress of the bucket type progressive machine, the mixture, the return material and the return material are mixed in the double shaft screw mixer. The returned material is unqualified after crushing and selection. The share of renewable data and new data is about 35:65 (when producing 1-4mm products).

2. Extrusion

The mixed fertilizer mixture is extruded by a roller extruder. The principle is that the data are formed by extrusion. The mixture enters the gap between the two rollers through the vertical screw feeder. During the extrusion, the pressure of the data increases gradually. When the gap between the two axes is small, the data pressure is large, and then gradually decreases to 0. In the extrusion process, the apparent density of the mixture can be improved by 1.5-3 times due to the decrease of the empty volume of the data. The extruded products are generally 5-20 mm thick plates (large pieces). The structure and dimension of roller npk fertilizer granulator are determined by many parameters, which are generally determined by data function and experiment.

3. Debris and classification

The plates formed in the roller extruder should be further crushed and graded to obtain the required particle size. Under the roller extruder, there is a specially designed plate crusher, where the plate is broken into small pieces in advance. The flakes are easy to transport and the subsequent crusher can further crush them. The damaged raw materials are divided into super large particles, product particles and fine particles on the multi-stage screen. The fine particles on the lower screen are recycled into the mixer and extruded out. The super large particles retained in the upper layer of the multi-stage screen need to be further broken. After the destruction, it comes back to pick. In the high-strength crusher, the softer sheet is broken into high-strength and wear-resistant particles. These products will not be crushed in the process of transportation and use. It is very important for the economy of chemical fertilizer extrusion granulation system to select the right equipment. The output value and capacity of a set of equipment are determined by the shape of particles (generally cube), the size range of particles (1-5 mm or 2-4 mm) and the cycle after crushing and selection.

4. Polishing and finishing

Generally, the product will go through one or two steps of polishing. The irregular particles are rounded by grinding wheels at the corners. The fine powder produced in the polishing process circulates through the screen (a layer of screen). Generally speaking, anti caking agents should be added to dressings. The product of this equipment is granular fertilizer (1-4mm) within a certain particle size range.

If only one kind of large granule fertilizer product is produced, such as granular potash fertilizer, granular ammonium sulfate or granular ammonium chloride, the investment will be further reduced due to the simple process and no need for weighing, measuring, crushing and mixing of raw materials. The fertilizer granulator machine price concessions.